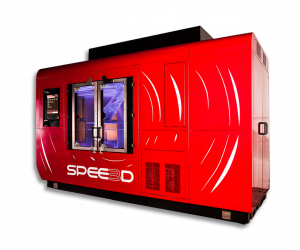

Phillips Federal Expands Rock Island Arsenal Additive Manufacturing Capability with a WarpSPEE3D Machine

Phillips Federal has signed an agreement to acquire a new WarpSPEE3D Metal AM printer from SPEE3D to be located at their Center of Innovation at the RIA.

DETROIT, MICHIGAN, USA, January 28, 2022 /EINPresswire.com/ -- Developed by Australian company SPEE3D, the world-leading WarpSPEE3D CSAM technology will be assigned at Phillips Federal's Center of Innovation co-located at the Rock Island Arsenal's Additive Manufacturing Center of Excellence. Phillips Federal and the US Army will use the WarpSPEE3D to further develop the facility’s Additive Manufacturing capability, and develop large format, parts-on-demand metal applications for the US Army.John Harrison, Global Director of Phillips Additive, states, “Since 2020, the unique high-speed capabilities of SPEE3D technology have proven to be an excellent addition in supporting the RIA’s manufacturing innovation objectives, and the scope of our P3 Program. The new WarpSPEE3D printer at the RIA’s Center of Excellence for Advanced Manufacturing facility will allow us to further our scope and make cutting-edge achievements in developing large-format applications for expeditionary forces in the US”.

Phillips Corporation, Federal Division, is the leading service provider and manufacturing partner to the United States Federal Government. Phillips Federal first added the metal Additive Manufacturing technologies of SPEE3D to support its Public Private Partnership (P3) and Additive Manufacturing programs at the US Army’s Rock Island Arsenal (RIA) in 2020.

In 2022, SPEE3D’s WarpSPEE3D technology will be added to the Center of Excellence for Advanced Manufacturing to support activities in material exploration and research, and the development and manufacture of future large-format applications and prototypes for the Army et al Armed Forces.

Bruce Colter, SPEE3D’s Vice President & General Manager of North America added, “We expect the delivery of this new WarpSPEE3D printer to provide Phillips Federal & the Rock Island Arsenal with additional capabilities from our patented Cold Spray AM technology, the fastest metal 3D printing capability in the world. WarpSPEE3D printers have demonstrated in field trials that they can make high-quality metal parts on-demand which are critical to keep military equipment & vehicles operational. The American AM space is growing rapidly, and SPEE3D’s technology is only growing with it”.

Since 2020, the WarpSPEE3D has been used often by Defense forces for an on-demand, deployable metal manufacturing capability. In 2020 and 2021, the Australian Army conducted several field trials with their WarpSPEE3D tactical printer at Mount Bundey, and Bradshaw Training Area during Exercise Koolendong. The field trials in 2020 resulted in over fifty case studies of printable parts and demonstrated that SPEE3D’s WarpSPEE3D printer was robust enough to operate in remote Australian bushland. In 2021, the program was extended to verify initial results, along with the establishment of new field trials and the Australian Army’s Additive Manufacturing Cell (AMC) technicians. In the 2021 field trials, the Australian Army successfully proved it is possible to 3D print, certify, validate, and replace armored vehicle parts in the field. The success of these trials demonstrated that additive manufacturing could play an important part in the future of Defense readiness.

“We believe this expansion is an exciting opportunity for SPEE3D and the DoD forces. Our smaller LightSPEE3D system has been used as part of the RIA program with great success. With a WarpSPEE3D, Phillips Federal & the Rock Island Arsenal will be able to explore a wider range of large, high quality, low-cost metal parts manufactured quickly,” says Byron Kennedy, CEO of SPEE3D.

More information on SPEE3D’s technology, including videos and case studies are available at: https://spee3d.com/

About SPEE3D

SPEE3D is an innovative supplier of metal-based additive manufacturing technology. SPEE3D focuses on the development, assembly, and distribution of machines and integrated system solutions based on the patented cold-spray technology. The products enable significantly faster, lower-cost, and more scalable production than traditional metal printing techniques for copper and aluminum and other materials.

Amy Frost

SPEE3D

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

EIN Presswire does not exercise editorial control over third-party content provided, uploaded, published, or distributed by users of EIN Presswire. We are a distributor, not a publisher, of 3rd party content. Such content may contain the views, opinions, statements, offers, and other material of the respective users, suppliers, participants, or authors.